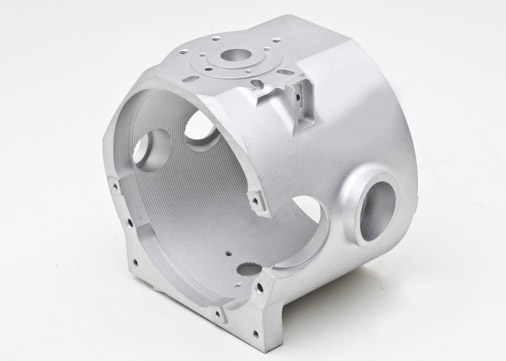

CNC Milling & CNC Turning

Our CNC precision machining footprint enables us to provide complete end-to-end solutions whatever the size, complexity, volume or materials of your product; utilizing the latest technologies, expertise and quality management.

CNC Precision machining benefits include:

– Low and medium volume production

– Medium to high complexity components

– Medium and large format mill and lathe machining

– Material flexibility – aluminum, titanium, steel, stainless steel, inconel, monel, greek astalloy, A286, plastics, brass, copper, cast iron, magnesium, tungsten

CNC Milling Capabilities

- Witco has three 5-axis milling machining centers and 21 mills overall. Our capabilities are listed below:

- X axis – Up to 50″

- Y axis – Up to 26″

- Z axis – Up to 25″

- A axis – Up to ±120˚

- B axis – 360˚

- Tolerance – .0001

CNC Turning Capabilities

- Witco has two 6-axis and two 4-axis turning centers. Our lathe department includes 16 CNC turning centers, 6 to 12 foot bar feeders, and 4 to 5 foot bar feeders. Our capabilities are listed below:

- Maximum Diameter – 23.62″

- Maximum Length – 80″

- Maximum Spindle Through Hole – 4.50″